Smash!

Some crazy people seem to have taken this idea even further, into total cold turkey territory. The result of this is SMaSH, or Single Malt and Single Hop, which sort of does what it says on the tin. Rather than picking from a massive list of ingredients, the SMaSH brewer can only choose three- one malt, one hop variety and one yeast strain. This can be a really interesting experiment for three reasons. Firstly, because you can drink a SMaSH beer and pretty accurately tell the flavour of each of those three ingredients. Secondly, because you could take those same ingredients and make very different beers depending on process variables like boil length and fermentation temperature. And thirdly, because it’s called SMaSH! Anyway, I was planning my next brew a few weeks ago and decided I had to have a go. My nominated ingredients: Canadian 2 row pale malt, Cascade hops and SafAle 04 British ale yeast.

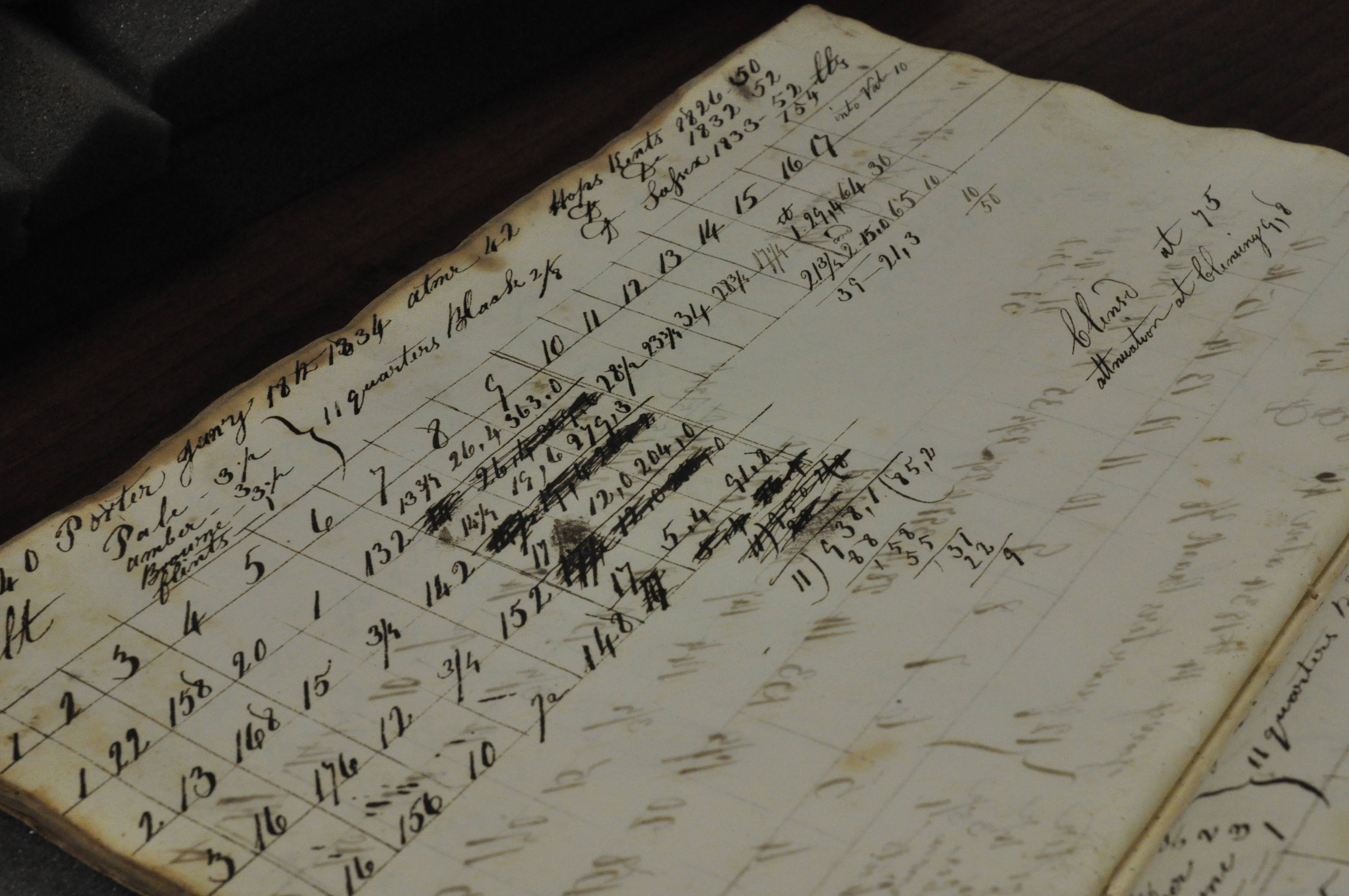

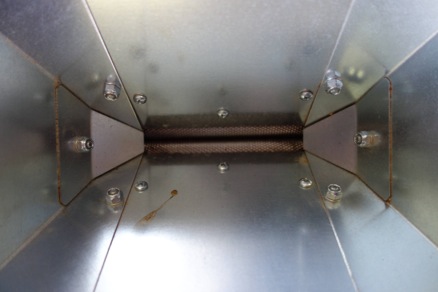

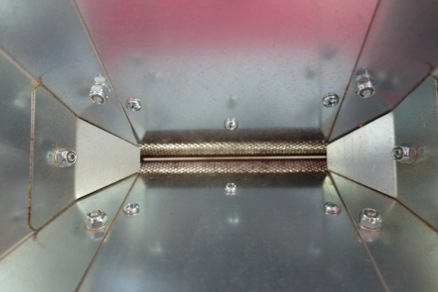

First things first though, I had a few issues to address from my last, less than successful, brew day. The biggest problem seemed to come from an overly fine grain crush, so I reset the rollers on my mill using a credit card to set the gap. I read that on a forum somewhere. The manual says something about feeler gauges and deadly accuracy, but I didn’t have any gauges, and the card trick seemed to do the job. Before and after:

So yeah, I’d recommend the credit card trick, which is pretty much as it sounds. I actually used my Ikea family card. You set the space at each end of the rollers, which gives at least a visually accurate spacing across the unit. This gave a crush which looked as it should- no massive bits of white endosperm, but also a relatively intact husk content.

As I said I’m used to chucking in a bunch of speciality malts, so I was surprised at how pale the mash run-off from just the two row malt was. To my eye anyway it wasn’t much darker than lager malts which I’d brewed with in the past. To give you an idea, here’s the strong wort, weak wort and post boil wort while I was taking gravity measurements.

This is a potential area of problem for SMaSH brewing. Although once upon a time it was common to brew dark beers with just one malt variety giving fermentable sugars and colour (porter and brown malt being a famous example), nowadays coloured malt tends to be not very fermentable and only used in small quantities with a more fermentable base malt. So brewing an all crystal malt beer would give a unfermentable wort and a very sweet beer. At least that’s the theory- I’ve never tried it. To counter this, SMaSH brewers sometimes use more lightly kilned speciality malts like Munich malt to give a darker colour and more body. However, it would be difficult to brew, for example, a dry stout using only one malt variety. For this reason, pale ales and IPAs are common SMaSH styles. Which I was quite happy with as I’m going through a bit of a pale ale drinking patch anyway.

It being a pale ale, the most important ingredient going into the beer was the hops. I chose cascades partly based on the success of commercial single hop cascade beers- Alexander Keith’s have been advertising their Cascade pale ale like crazy, including heavy Super Bowl rotation, and I had to one-up them. It’s also the hop more than any other credited with kicking off the microbrewing revolution, so it felt like time to pay my dues.

And, you know what, despite having its time in the sun as the hop de jour, a crown passed down to some other hops beginning with the letter C, a bunch of Aussie upstarts and lately some hops that are so new and cool they don’t even have names yet, Cascade is still kicking butt like its 1995. Or 1971, which is apparently when it was first bred, which makes me feel like a young upstart. Whatever, it tastes really good.

To make the most out of such a great ingredient, I made hop additions at 90 minutes, 10 minutes and 0 minutes to flame out, as well as racking onto some pellets in primary (unfortunately I had to leave the beer for a couple of weeks so couldn’t dry hop in a secondary vessel as I usually would). Another thing I mentioned in my last post was some difficulty with pellet hops. Well another great thing about Cascade is its availability, and I had no problem getting hold of enough leaf hops to use them exclusively during the boil. Which is more than can be said for most other varieties, but that’s another story.

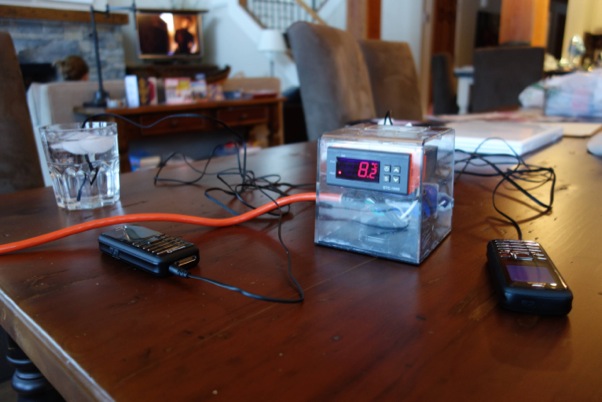

So, what you’ll be dying to know, other than where I got my AWESOME R2-D2 bottle opener from (I don’t know, my even more awesome gal gave it to me!), is- is it any good? And I’d say yes, it’s great. Substantially better than the last brew in fact, which is always heartening. If it has any flaw it’s that I’d like it to be bigger and hoppier, but the recipe was designed to be a sessionable pale ale, which is pretty much what it is. It’s quite Sierra Nevada Pale Ale in hop character, but the Brit ale yeast gives it a bit more fruitiness compared to the Chico yeast strain. Which, to be honest, I’d use more if it weren’t for its piss poor flocculation. In fact I’ve got a wyeast pack of it in the fridge, so a reboot may be in order. As for body, it’s pleasantly dry which I’m quite liking at the moment compared to more caramely, darker ‘pale ales’. So yeah, overall, I’m pretty chuffed, and it’s disappearing fairly quickly. I get the feeling I might have to ramp up the hops and ABV for next time- I think the west coast is rubbing off on me. Obviously there’s considerable room for improvement, especially with yeast/fermentation. In fact, that’s probably going to take up a couple of posts in the near future, as I’m expanding my kit to include at least some degree of control over yeast pitching rates and temperature control. So I’ll have even fewer excuses if I make anything pants from now on. Here’s a little teaser of what I’ve been putting together this evening (no fires/electrocution yet):

Thermostatically controlled phone charging (Also GoT arrived in the post this morning...)